The first Dutch bio-LNG installation: Construction has started

Renewi, Nordsol and Shell have started the construction of the first bio-LNG installation in Amsterdam Westpoort. The new bio-LNG installation is an extension for the current processing of, among other things, outdated products from the supermarkets.

With an investment of several millions, the technical partner Nordsol will be the first to produce bio-LNG in the Netherlands. The development of this production location in Amsterdam Westpoort paves the way for Dutch bio-LNG.

The three initiators each fulfill a unique role in the new waste-to-energy chain. Renewi collects organic waste throughout the Netherlands, such as expired products, processes this waste and converts it into biogas during its fermentation. The Nordsol installation then processes this biogas into bio-LNG. Finally, Shell sells this bio-LNG at its LNG filling stations.

Compared to diesel, bio-LNG has lower CO2 emissions. Moreover, bio-LNG is made from organic waste and not from fossil sources. Bio-LNG will play an important role in the coming years in making heavy road and water transport more sustainable because the electrification of trucks and ships is difficult.

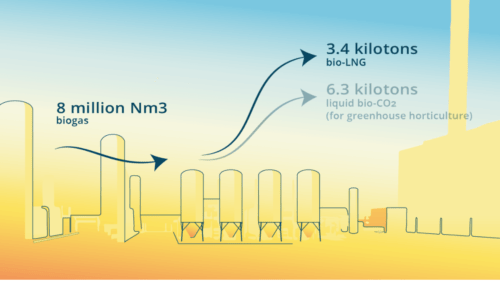

In the Nordsol installation, the biogas extracted from organic waste is converted into bio-LNG and liquid bio-CO2, a transparent and fair supply chain. Biogas consists of approximately 60% methane and 40% carbon dioxide (CO2). The technology makes it possible to efficiently separate pure methane from the biogas and liquefy it into bio-LNG. The CO2 by-product is reused in the market and therefore ensures an additional CO2 emission reduction. This leads to a 100% CO2 neutral fuel.

The installation will be operational within a year, as the standardized modules are produced elsewhere and connected on the Renewi site. The installation will soon produce 3.4 kilotons of bio-LNG per year. This allows more than 13 million kilometers of CO2 neutral driving. To give an idea – this is more than 370 times around the globe.